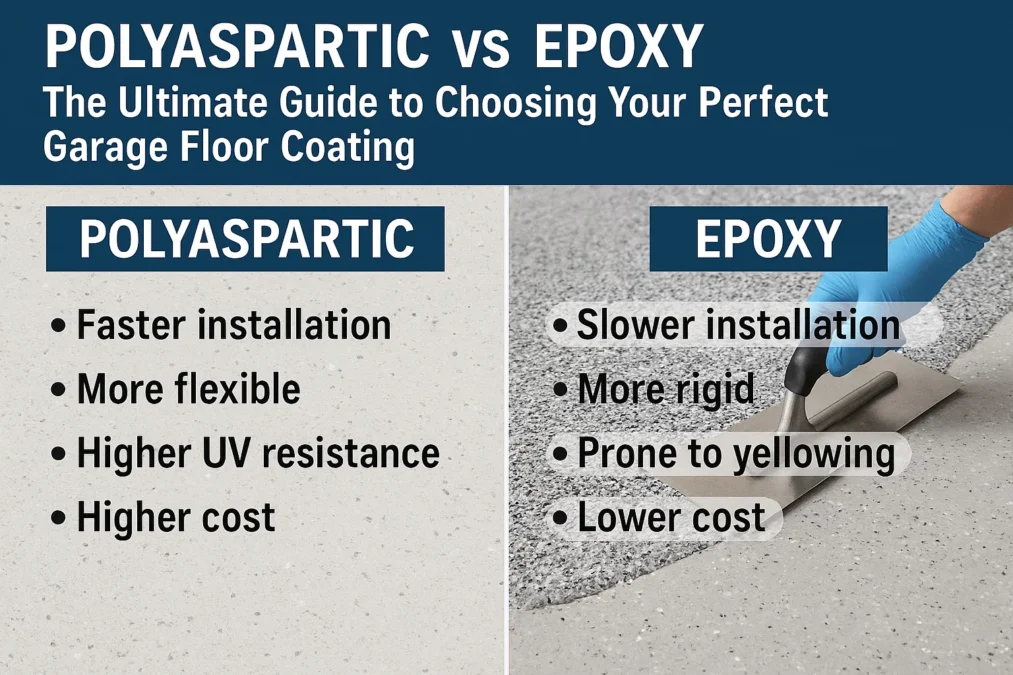

So, you’ve decided to transform your garage floor. You’re tired of the dusty, stained concrete and envision a sleek, durable, and easy-to-clean surface that makes your garage a space you’re proud of. But as you start your research, you quickly run into a major decision: polyaspartic vs epoxy. You’ll find passionate advocates for both, and it can be confusing to wade through the marketing claims to find the truth.

This isn’t just a simple choice between two similar products. It’s a decision that involves weighing factors like your budget, your timeline, how you use your garage, and the local climate. Choosing the right coating can mean the difference between a floor that looks fantastic for decades and one that chips, stains, or peels in just a few years. We’re here to cut through the noise and give you a clear, expert, and unbiased comparison. We’ll dive deep into the chemistry, performance, installation process, and real-world costs of both polyaspartic and epoxy coatings. By the end of this guide, you’ll have all the information you need to confidently choose the best floor coating for your specific situation. Let’s get started by understanding what these two materials actually are.

What is Epoxy? The Time-Tested Workhorse

Epoxy flooring has been the go-to solution for industrial, commercial, and residential garage floors for decades. At its core, epoxy is a thermosetting polymer created by a chemical reaction between a resin and a hardener. When these two parts are mixed, they undergo a process called “curing,” transforming from a liquid state into an incredibly hard, rigid, and durable plastic-like surface. This curing process is what gives epoxy its legendary strength and adhesion.

Traditional 100% solids epoxy systems are known for creating a thick, glossy, and seamless surface that bonds tenaciously to properly prepared concrete. This bond creates a floor that is highly resistant to chemicals like oil, gasoline, and household cleaners, making it an excellent choice for protecting your concrete slab from permanent stains and damage. The thick, glossy finish also provides a bright, reflective surface that can dramatically improve the lighting in your garage. For many homeowners, the classic high-gloss “showroom” finish is the aesthetic they desire.

The Evolution of Epoxy Coatings

It’s important to note that not all epoxy products are created equal. The market is flooded with inexpensive, water-based or solvent-based epoxy kits found at big-box stores. These products often contain lower levels of epoxy solids and are diluted to make application easier for the DIYer. While they can provide a decent cosmetic upgrade, they generally lack the durability, thickness, and long-term performance of professional-grade, 100% solids epoxy systems. For a garage floor that will see real-world use from cars, tools, and foot traffic, investing in a professional-grade epoxy system is highly recommended. The longevity and performance are well worth the additional cost.

What is Polyaspartic? The Modern Powerhouse

Polyaspartic coatings are the newer, high-tech player in the floor coating arena. Chemically speaking, polyaspartic is a type of aliphatic polyurea. Think of it as a advanced, hybrid derivative of polyurethane with some very special properties. It was originally developed in the 1990s as a protective coating for industrial and commercial applications where extreme durability and fast turnaround times were critical. Over the years, its formulation has been refined for the residential market, and it has gained immense popularity for its user-friendly characteristics and superior performance in several key areas.

The most significant advantage of a polyaspartic coating lies in its curing time. Unlike epoxy, which cures through a slower chemical reaction, polyaspartic cures incredibly fast. It can be walked on in just a few hours and can often handle vehicle traffic within 12-24 hours. This rapid cure time is a massive benefit for homeowners who can’t afford to have their garage out of commission for several days. Furthermore, polyaspartics are much more flexible than the rigid epoxy. This flexibility allows them to expand and contract with the concrete substrate as temperatures fluctuate, which greatly reduces the risk of cracking or delamination over time.

The Versatility of Polyaspartic Coatings

Another key feature of polyaspartic is its application versatility. It can be applied in a much wider range of temperatures and humidity levels compared to epoxy. Epoxy is notoriously finicky about application conditions, often requiring a specific temperature range (typically between 50-90°F) and low humidity to cure properly. Polyaspartic, on the other hand, can be applied in temperatures as low as -30°F and in conditions with higher humidity. This makes it a more reliable choice for garage installations in climates with unpredictable weather or for projects that need to be completed during colder months.

Key Differences in Performance and Durability

When you’re investing in a garage floor coating, you want it to last. The battle of polyaspartic vs epoxy really heats up when we look at long-term performance. Both are incredibly durable, but they excel in different ways. Epoxy provides exceptional compressive strength, meaning it can handle heavy, stationary loads without denting. Its thick, rigid build is excellent for resisting impacts from dropped tools. However, that rigidity can also be a weakness if the underlying concrete cracks or shifts, as the epoxy coating may crack along with it.

Polyaspartic counters with superior tensile strength and flexibility. It can stretch and move, which makes it highly resistant to cracking from substrate movement. It also boasts exceptional abrasion resistance, meaning it holds up better to the constant scuffing and scraping from foot traffic, car tires, and moving equipment. In terms of UV stability, polyaspartic is the clear winner. Its aliphatic nature means it is inherently resistant to yellowing or degrading when exposed to sunlight. Epoxy, unless it has a UV-resistant topcoat, will amber and yellow over time if it receives direct sunlight, which is a crucial consideration if your garage has windows or the door is frequently open.

Chemical and Stain Resistance

Both coatings offer excellent resistance to a wide array of chemicals commonly found in a garage, including motor oil, brake fluid, gasoline, and antifreeze. However, epoxy’s non-porous surface can be slightly more susceptible to staining from certain aggressive chemicals if spills are not cleaned up promptly. Polyaspartic’s combination of hardness and chemical inertness makes it arguably slightly more stain-resistant overall. Hot tire pickup is another critical factor. This occurs when the hot tires from a freshly parked car soften the coating and, upon lifting, pull the coating off the floor. Both modern epoxy and polyaspartic systems are formulated to resist this issue, but high-quality polyaspartic coatings are often considered the gold standard for hot tire resistance.

The Installation Process: A Tale of Two Timelines

The installation process is where the differences between polyaspartic and epoxy become most apparent, and it often has a significant impact on the final decision for homeowners. A proper installation for either system is a multi-step process that is heavily dependent on one critical factor: surface preparation. In both cases, the concrete must be clean, dry, and free of any contaminants, oils, or previous coatings. This almost always requires professional-grade diamond grinding or shot blasting to open the pores of the concrete and create a profile for the new coating to mechanically bond to. There are no shortcuts here; poor preparation is the primary cause of coating failures for both types of systems.

Once the prep is complete, the application diverges. A full epoxy system typically involves multiple coats: a primer or seal coat, one or two flood coats of the colored epoxy, and often a clear protective topcoat for added UV and abrasion resistance. Each coat requires a specific amount of time to cure before the next can be applied. This multi-coat process, combined with the slower curing nature of epoxy, means the entire project can take three to five days from start to finish before you can park a car on it.

The Speed of Polyaspartic Installation

The installation of a polyaspartic coating is dramatically faster. While the surface preparation is identical and just as important, the application and curing are where it shines. A polyaspartic system can often be completed in a single day. Because it cures so quickly, multiple coats—such as a primer, color coat, and clear topcoat—can be applied within a few hours of each other. You can typically walk on the floor within 4-6 hours and park a car on it within 12-24 hours. This speed minimizes disruption to your daily life and is a massive advantage for commercial settings where downtime costs money. However, this fast cure time also makes the application a job for experienced professionals, as there is very little margin for error during installation.

Cost Analysis: Initial Investment vs. Long-Term Value

Let’s talk numbers, because budget is a major factor for most homeowners. In the direct comparison of polyaspartic vs epoxy cost, epoxy is generally the less expensive option upfront. A professional-grade, 100% solids epoxy floor coating system will typically cost less per square foot than a comparable polyaspartic system. The material cost for polyaspartic is higher due to its advanced chemistry and performance benefits. This price difference can be significant, with polyaspartic often costing 20-50% more than a high-quality epoxy for the materials alone.

However, it is crucial to look beyond the initial price tag and consider the long-term value. A polyaspartic coating’s exceptional durability, UV stability, and flexibility can translate into a longer functional lifespan with less need for maintenance or repair. While a well-installed epoxy floor can last 10-20 years, a polyaspartic floor can often last 20+ years without showing significant wear. When you factor in its superior performance against yellowing and cracking, the higher initial investment in a polyaspartic coating can be justified over time. It becomes a classic “pay more now, save more later” scenario.

Factoring in Labor Costs

It’s also worth noting that while polyaspartic materials are more expensive, the labor cost for installation can sometimes be lower due to the drastically reduced project timeline. A professional crew can complete a polyaspartic job in one day instead of three or four, which can offset some of the material cost difference. However, this is highly dependent on the contractor and their pricing structure. Always get detailed quotes that break down material and labor costs for both systems to make an accurate comparison for your specific project.

Aesthetic Options and Customization

Your garage floor is a canvas, and both epoxy and polyaspartic offer a wide range of aesthetic possibilities. Epoxy is famous for its deep, wet-looking, high-gloss finish. It’s the classic look that many people associate with a premium garage. Epoxy is also the preferred material for creating intricate flake systems. In these systems, colored vinyl chips are broadcast (sprinkled) onto the wet epoxy coat, creating a highly customizable, decorative, and slip-resistant surface. The excess chips are then scraped off and a thick, clear topcoat is applied to seal everything in, creating a durable and visually stunning floor.

Polyaspartic coatings are equally capable when it comes to aesthetics. They can be formulated to achieve a high-gloss, satin, or even matte finish. They are also perfectly suited for flake finishes, and many contractors use polyaspartic as the clear topcoat over an epoxy color base because of its superior UV resistance and durability. Furthermore, polyaspartic can be used to create metallic epoxy-like effects, where pigments are manipulated to create unique, swirling, marbled patterns. While epoxy has a longer history with these decorative techniques, polyaspartic has caught up and can deliver virtually any look you can imagine.

Clarity and Color Stability

One subtle but important aesthetic difference is in the clarity of the topcoat. Polyaspartic clear coats are renowned for their exceptional clarity and “wet look” that enhances the depth of any flakes or pigments beneath them. And as mentioned before, their UV stability ensures that the colors and clarity remain vibrant and unchanged for years, even in a sun-drenched garage. An epoxy topcoat without UV inhibitors will eventually yellow, which can alter the appearance of your floor, muting bright white chips or giving a slight tint to the entire surface.

E55 AMG vs Panamera: The Clash of German Titans Across Generations

Ideal Use Cases: Which Coating is Right for You?

The best way to decide between polyaspartic and epoxy is to align the coating’s strengths with your specific needs, lifestyle, and garage environment. There is no one-size-fits-all answer, but certain scenarios clearly point towards one option being superior to the other.

An epoxy coating is an excellent choice if you are on a tighter budget but still want a highly durable and beautiful floor. It’s perfect for garages that are used primarily for parking cars and general storage, and where the floor is not exposed to direct sunlight for prolonged periods. If you have a stable concrete slab with no history of significant cracking or moisture issues, a professionally applied epoxy system will provide decades of reliable service. It’s the proven, cost-effective workhorse.

When to Choose Polyaspartic

You should strongly consider investing in a polyaspartic coating if any of the following apply to you: You need a fast installation and cannot have your garage out of commission for several days. Your garage has windows or the door faces the sun, exposing the floor to significant UV radiation. You live in a climate with large temperature swings, as the flexibility of polyaspartic will better handle the expansion and contraction of the concrete. The garage is a high-traffic area, used as a workshop, gym, or play area where abrasion resistance is paramount. You are looking for the absolute maximum in long-term durability and are willing to pay a premium for it. For these situations, the benefits of polyaspartic vs epoxy are substantial and well worth the investment.

Comparison Table: Polyaspartic vs Epoxy at a Glance

| Feature | Epoxy | Polyaspartic |

|---|---|---|

| Durability | Excellent compressive strength, impact resistant. Can be brittle. | Superior tensile strength, abrasion resistance, and flexibility. |

| Cure Time | 24-72 hours to walk, 3-5+ days for vehicle traffic. | 2-4 hours to walk, 12-24 hours for vehicle traffic. |

| UV Stability | Will amber and yellow without a UV-resistant topcoat. | Inherently UV-stable; will not yellow or degrade. |

| Application Temp | Sensitive; typically 50-90°F. High humidity can cause issues. | Very wide range; can be applied from -30°F to 140°F+. |

| Chemical Resistance | Excellent resistance to most automotive chemicals. | Excellent, with arguably slightly better stain resistance. |

| Hot Tire Resistance | Good (in modern formulations). | Excellent. |

| Lifespan | 10-20 years with professional installation. | 20+ years with professional installation. |

| Cost | Generally lower initial material cost. | Higher initial material cost, but potentially better long-term value. |

| Best For | Budget-conscious projects, stable slabs, minimal UV exposure. | Fast installations, high UV areas, climates with temperature swings, maximum longevity. |

What the Pros Say: Quotes on the Matter

To get a real-world perspective, it’s helpful to hear from the experts who install these floors every day.

“A professional 100% solids epoxy floor is a fantastic product that has served homeowners well for years. But when a client asks me for the best possible protection with the least amount of hassle, I almost always steer them towards polyaspartic. The speed of installation and the peace of mind from the UV stability are huge selling points that justify the extra cost for most people.” – Mark Jennings, Owner of Premier Garage Floors.

“The key to a successful floor, whether it’s epoxy or polyaspartic, is 90% in the preparation. You can have the most expensive coating in the world, but if the concrete isn’t properly cleaned and profiled, it will fail. We choose our coating system based on the client’s garage, their budget, and how they plan to use the space. There’s a right tool for every job.” – Sarah Chen, Lead Technician at DuraCoat Solutions.

Frequently Asked Questions (FAQ)

What is the main disadvantage of polyaspartic coatings?

The primary disadvantage of polyaspartic coatings is their higher initial cost compared to epoxy. The advanced chemistry required to create the material makes it more expensive. Additionally, the extremely fast cure time, while a benefit for the homeowner, can be a challenge for installers, making it less suitable for DIY attempts and necessitating a highly experienced professional for a flawless application.

Can you apply a polyaspartic topcoat over an epoxy floor?

Yes, this is a very common and highly effective hybrid approach. Many professional installers will use an epoxy base coat for its excellent adhesion and cost-effectiveness, and then apply a polyaspartic clear topcoat. This combines the strength and affordability of epoxy with the superior UV resistance, abrasion resistance, and quick curing properties of polyaspartic for the final, protective layer.

Is a polyaspartic floor slippery when wet?

Like any smooth, glossy surface, a polyaspartic floor can be slippery when wet. However, this is easily mitigated. During installation, anti-slip additives can be mixed into the final clear topcoat. These additives create a microscopic texture that significantly improves traction without compromising the smooth, easy-to-clean nature of the surface. Another option is to use a decorative flake system, where the broadcast chips naturally create a more slip-resistant finish.

How long does an epoxy garage floor actually last?

The lifespan of an epoxy garage floor depends heavily on the quality of the installation (especially surface preparation) and the daily wear and tear it receives. A low-quality, DIY kit might last only a year or two before chipping and peeling. A professionally applied, 100% solids epoxy system on a well-prepared slab can easily last 10 to 20 years, and often longer with proper care.

Can I install an epoxy floor myself?

While DIY epoxy kits are widely available, achieving a professional, long-lasting result is very challenging for a novice. The critical steps—especially the concrete preparation—require specialized equipment and knowledge. Mistakes in mixing, application, or timing can lead to bubbles, uneven coverage, or premature failure. For a garage floor that needs to withstand automotive use, hiring a professional is strongly recommended to ensure the job is done correctly.

Which coating is better for a garage with moisture issues?

Neither epoxy nor polyaspartic will properly adhere to a concrete slab with active moisture vapor transmission. The moisture will create pressure that blisters and delaminates the coating. Before considering any coating, a moisture test should be performed. If moisture is present, a professional must first address it with an appropriate moisture mitigation primer or system designed specifically for that purpose, which can then be topped with either coating.

Conclusion

The choice between a polyaspartic and an epoxy garage floor coating is not about finding a single “best” product, but rather about finding the right product for your specific needs, budget, and circumstances. Both are superior alternatives to bare concrete, offering protection, cleanliness, and a transformed aesthetic.

Epoxy stands as the proven, cost-effective champion. It delivers exceptional durability and a beautiful, glossy finish at a more accessible price point. For garages with stable concrete, limited UV exposure, and where project timeline is not a critical factor, a professional epoxy system remains an outstanding choice that will provide satisfaction for many years.

Polyaspartic emerges as the modern, high-performance alternative. Its superior UV stability, incredible durability, remarkable flexibility, and lightning-fast installation process justify its higher initial cost. If you value long-term value over short-term savings, need a quick turnaround, or have a garage exposed to sunlight and temperature fluctuations, investing in a polyaspartic coating is the wise decision for a truly worry-free floor.

Ultimately, the most important factor in the success of either system is the quality of the installation. A poorly installed polyaspartic floor will fail, while a expertly installed epoxy floor will thrive. Choose a reputable, experienced contractor who properly prepares the concrete and uses high-quality materials. By carefully weighing the differences outlined in this guide and consulting with a professional, you can confidently choose the perfect coating to create a garage floor you’ll love for decades to come.