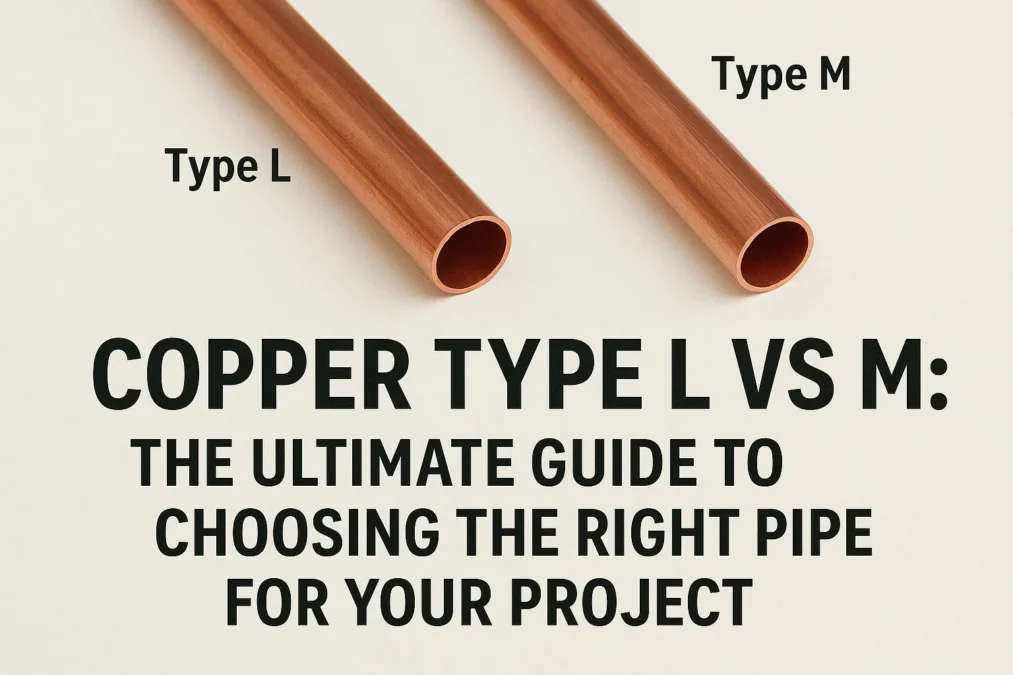

Copper Type L vs M: Walking down the plumbing aisle of your local hardware store, you’re faced with a rainbow of options. But it’s not about color; it’s about a simple letter stamped on the side of a copper pipe. For anyone tackling a plumbing project, whether you’re a seasoned DIYer or a curious homeowner, understanding the difference between Copper Type L and Type M is crucial. This isn’t just plumbing jargon—it’s the key to a safe, durable, and code-compliant water system in your home. Choosing the wrong type can lead to leaks, pressure problems, and even catastrophic failures down the line.

This comprehensive guide is designed to demystify these two common types of copper pipe. We’ll dive deep into what those letters mean, explore their specific strengths and weaknesses, and lay out exactly where and when you should use each one. By the end, you’ll be equipped with the knowledge to confidently select the right pipe, communicate effectively with contractors, and ensure your plumbing stands the test of time. Let’s untangle the world of copper tubing and ensure your next project is built on a solid foundation.

Understanding the Basics of Copper Water Tube

Before we pit Type L against Type M, it’s essential to understand what we’re actually talking about. Copper pipe used for plumbing is technically referred to as “tube,” and it’s manufactured to meet specific standards set by the American Society for Testing and Materials (ASTM). These standards ensure consistency in size, wall thickness, and performance across all manufacturers. The most common standard for water service and distribution is ASTM B88, which covers seamless copper water tube.

The primary difference between all types of copper tube—including Type K, L, M, and DWV (Drain-Waste-Vent)—is the wall thickness. They all have the same outside diameter for any given nominal size (e.g., a 1/2-inch pipe has the same OD whether it’s Type L or M). This allows them to fit the same fittings. What changes is the inside diameter. A thicker wall means a smaller hole running through the center of the pipe. This wall thickness directly influences the pipe’s pressure rating, durability, cost, and suitability for different applications. Type K has the thickest walls, followed by Type L, with Type M having the thinnest walls commonly used for pressurized water lines.

A Deep Dive into Copper Type L

Copper Type L is often considered the workhorse of residential plumbing. The “L” stands for nothing more than its place in the hierarchy of wall thickness. It strikes a balance between the robust, heavy-duty nature of Type K and the more economical, thinner-walled Type M. You can identify Type L pipe by its distinctive blue printing and stripe, making it easy to distinguish from the red of Type M and the yellow of Type K on the shelf.

This type of copper tube is versatile and approved for a wide range of applications both inside and outside the home. Its wall thickness gives it a higher pressure rating than Type M, making it the preferred and often required choice for underground water service lines that run from the municipal main to your house. It’s also extensively used for interior water distribution, including hot and cold water lines running through walls, floors, and ceilings. Its added strength provides a margin of safety against accidental impact during and after installation and helps it better withstand the occasional water hammer event.

Key Characteristics and Common Uses of Type L

The defining characteristic of Type L is its intermediate wall thickness. For example, in a 1/2-inch nominal size, Type L has a wall thickness of 0.040 inches, while Type M of the same size has a wall thickness of 0.028 inches. This might seem like a small difference on paper, but it translates to a significant increase in strength and pressure capacity. The pressure rating for Type L is higher across all sizes compared to Type M, which is a critical factor for main supply lines and systems with higher static pressure.

Because of this resilience, Type L is the default choice for many professional plumbers for in-wall residential plumbing. It’s also mandated by many local plumbing codes for any copper piping that will be buried underground as a service line. The thicker wall is more resistant to the external pressures of the soil and potential damage from rocks or shifting earth. Furthermore, Type L is available in both rigid hard-temper and flexible soft-temper coils (often referred to as “ACR” tube for air conditioning and refrigeration, but it’s the same ASTM B88 specification), adding to its versatility for projects that require bending around obstacles.

A Deep Dive into Copper Type M

On the other side of the ring, we have Copper Type M. As the thinnest-walled tubing approved for use in residential pressurized water systems, Type M is the most economical choice. Its identifying mark is red printing and a red stripe. Its thinner walls mean it uses less copper, which directly translates to a lower material cost. This price advantage can be substantial on larger projects, making it an attractive option for budget-conscious builders and homeowners.

However, this cost-saving comes with trade-offs. The reduced wall thickness means Type M has a lower pressure rating than Type L. It is also more susceptible to damage from physical impact, abrasion, and the corrosive effects of highly acidic or aggressive water. It is not suitable for any underground use, as the external pressure and potential for soil corrosion could compromise the thinner walls. Its application is primarily limited to the interior, above-ground water distribution within a single-family or multi-family dwelling.

Key Characteristics and Common Uses of Type M

The primary advantage of Type M is unmistakably its lower cost. For a large new construction project with hundreds of feet of plumbing, using Type M over Type L can result in significant savings on material costs. Its thinner walls also make it slightly easier to cut and deburr, though the difference is minimal for anyone with proper tools. Because the outside diameter is identical to other types, it uses all the same fittings and valves, so there are no savings or complications on that front.

The common and acceptable uses for Type M are typically governed by local building codes. In many areas, it is approved for above-ground, indoor hot and cold water distribution in residential buildings. This means the lines that run from your main shutoff to your sinks, toilets, and showers can often be Type M. It is crucial to never use Type M for fire sprinkler systems, gas lines, oil lines, or any commercial application. Its use is strictly limited to certain residential pressure applications. Always, without exception, check your local plumbing code before choosing Type M for a project.

The Critical Differences: A Head-to-Head Comparison

Now that we have a clear picture of each type individually, let’s put them side-by-side. The choice between Copper Type L and Type M isn’t about which one is universally “better”; it’s about which one is appropriate for your specific application. The differences are distinct and have real-world consequences for the performance and longevity of your plumbing system.

The most significant difference is, of course, the wall thickness and the resulting pressure rating. This isn’t just a theoretical distinction. In a high-pressure system, or during a water hammer event (a pressure surge caused when water flowing quickly is forced to stop or change direction suddenly), the thicker walls of Type L provide a crucial safety buffer. Type M, while rated for normal residential pressures, has less tolerance for these pressure spikes and is more prone to failure under such conditions.

Durability, Cost, and Code Considerations

Durability extends beyond just pressure handling. Type L’s thicker walls make it more resistant to physical damage. If a pipe is accidentally nicked by a drill bit or hit with a tool during a renovation, Type L is more likely to survive with minor damage, whereas Type M could be compromised. This durability also translates to better longevity in areas with slightly aggressive water, as it will take longer for corrosion to eat through a thicker wall.

The cost difference is a major driving factor. Type M can be 20-30% cheaper than Type L for the same length of pipe. For a small repair, this difference might be negligible. For an entire house replumb, it can amount to hundreds of dollars saved. However, this upfront saving must be weighed against the potential for higher long-term risk. Finally, and most importantly, are code considerations. Local plumbing codes have the final say. Some jurisdictions prohibit the use of Type M entirely. Others restrict it to low-rise residential buildings. Some allow it but require Type L for the main supply risers. Ignoring code can lead to failed inspections, denied insurance claims, and serious safety issues.

| Feature | Copper Type L | Copper Type M |

|---|---|---|

| Wall Thickness | Thicker (Intermediate) | Thinnest (for pressurized water) |

| Inside Diameter | Smaller for same nominal size | Larger for same nominal size |

| Pressure Rating | Higher | Lower |

| Durability | More durable, resistant to physical damage | Less durable, more easily damaged |

| Cost | More expensive | Less expensive |

| Primary Applications | Underground service lines, interior water distribution, commercial, radiant heating | Above-ground indoor water distribution (residential only) |

| Code Acceptance | Widely accepted for almost all water applications | Restricted by many local codes; never allowed underground |

| Color Code | Blue | Red |

When to Use Type L and When to Use Type M

Making the final decision can be simplified by following some general rules of thumb. These guidelines are based on safety, code compliance, and best practices. Remember, when in doubt, always default to the more robust option or consult a licensed professional plumber. The cost of upgrading to Type L is almost always less than the cost of repairing water damage from a failed pipe.

You should always choose Copper Type L for the following situations: any underground water service line between the city main and your home; the main water supply riser in a multi-story building; any plumbing that will be encased in concrete or buried in a slab; homes with particularly high water pressure (above 80 PSI); commercial plumbing applications; and any situation where local code explicitly requires it. If you are unsure about your water pressure or the local code, Type L is the safe and conservative choice that will rarely, if ever, be wrong.

Opting for Type M: A Calculated Decision

The decision to use Copper Type M should be a conscious, calculated one. It is only suitable for the interior, above-ground hot and cold water lines within a single-family home or a low-rise apartment building. You should only consider it if: your local plumbing code explicitly permits its use for your specific application; your home’s water pressure is within normal municipal limits (typically 40-80 PSI); the piping runs are in protected areas like wall cavities where they won’t be subject to physical abuse; and the budget is a primary concern for a new construction project. It is a “code-minimum” option in many areas and should be selected with that understanding.

Installation Tips and Professional Insights

Whether you choose Type L or Type M, proper installation is paramount. Copper plumbing is a fantastic system when installed correctly but can be a source of headaches if done poorly. The installation process for both types is identical—they use the same fittings, flux, solder, and techniques. The key is care and precision.

One pro tip is to always support the pipe adequately with approved hangers or straps. Copper pipe can sag over long runs, especially with hot water lines that expand and contract. Proper support prevents stress on the joints. Secondly, when cutting the pipe, always use a sharp tubing cutter and meticulously remove all internal and external burrs. A leftover burr inside the pipe will create turbulence and noise and can lead to erosion corrosion over decades. Finally, ensure the pipes are perfectly clean and bright before soldering. Any dirt, moisture, or oxidation will prevent the solder from forming a perfect seal, leading to leaks.

Why Consulting a Professional is Often the Best Choice

While DIY plumbing can be rewarding, knowing when to call a professional is a sign of a wise homeowner. A licensed plumber doesn’t just know how to solder a joint; they bring a wealth of knowledge about local codes, pressure dynamics, and best practices. They can perform a pressure test on your system to ensure there are no leaks before the walls are closed up.

They will also know the specific code requirements for your area regarding copper type l vs m. What might be allowed in one town could be prohibited in the next. A professional installation comes with a guarantee of both workmanship and compliance, protecting your investment and ensuring the safety of your home. For any major repiping project, underground work, or if you have any doubt at all, getting a few quotes from reputable plumbers is a highly recommended step.

Beyond Type L and M: Other Copper Types and Alternatives

While L and M are the most common encounter in residential plumbing, it’s worth briefly mentioning their siblings. Type K copper tube has the thickest walls and is colored green. It is used for underground applications where extra durability is needed, such as when a pipe is direct-buried without a protective sleeve or in areas with highly corrosive soils. It’s also standard for well pump lines and in some commercial and fire sprinkler applications.

DWV copper (Drain-Waste-Vent) has the thinnest walls of all and is colored yellow. As the name implies, it is only designed for non-pressurized drainage, waste, and vent lines. It should never be used for pressurized water supply. Furthermore, the world of plumbing isn’t limited to copper. In many modern homes, cross-linked polyethylene (PEX) tubing has become an incredibly popular alternative. PEX is flexible, resistant to freeze cracking, often cheaper, and easier to install with push-fit or crimp fitting systems. Chlorinated Polyvinyl Chloride (CPVC) is another plastic alternative that is glued together rather than soldered. Each material has its pros and cons, and the choice between copper, PEX, or CPVC is a whole other conversation for homeowners to consider.

0w20 vs 5w20: The Ultimate Guide to Choosing the Right Oil

Conclusion

The debate between copper Type L and Type M ultimately boils down to a balance of strength, cost, and code compliance. Type L, with its thicker walls and higher pressure rating, is the versatile, durable, and safe choice for almost every application, from underground service lines to in-wall water distribution. Type M, with its thinner walls and lower cost, is a budget-friendly option restricted to specific above-ground residential uses where local codes permit. There is no one-size-fits-all answer, but by understanding their key differences—wall thickness, pressure capacity, and approved applications—you are now equipped to make an informed decision. Always prioritize safety and longevity over short-term savings, and when your project’s requirements are unclear, consulting your local building code or a professional plumber is the best way to ensure your home’s plumbing system is built to last.

Frequently Asked Questions (FAQ)

Can I mix Copper Type L and Type M in the same house?

Yes, it is technically possible to mix types, as they have the same outside diameters and use the same fittings. However, it is generally not recommended. Mixing can create confusion for future work and may complicate code compliance. If you do mix them, a best practice is to use the more robust Type L for all main supply lines and risers and restrict Type M to shorter, branch lines to fixtures, provided the code allows it.

Is Copper Type M strong enough for my home’s water pressure?

In most cases, yes, but it depends. Typical municipal water pressure ranges from 40 to 80 PSI (pounds per square inch). Type M has a pressure rating that exceeds this in most sizes. However, if your home has consistently high pressure (above 80 PSI) or is prone to severe water hammer, Type L is a much safer and more reliable choice. It’s always a good idea to test your home’s static water pressure with a gauge before making a decision.

Why is Type L required for underground use?

Type L is required for underground water service lines because it can withstand the external pressure from the soil and backfill without collapsing or deforming. Its thicker walls are also more resistant to damage from rocks and potential corrosion from soil chemicals. The thinner walls of Type M are not designed to handle these external stresses and could fail if buried.

Do plumbers prefer using Type L or Type M?

Many professional plumbers have a strong preference for Type L due to its superior durability and versatility. It allows them to use one type of pipe for both underground and indoor applications, simplifying their material list. The extra cost of Type L is often seen as cheap insurance against callbacks and potential problems. However, some production home builders may opt for Type M on large-scale projects to save on material costs where code permits.

How does the inner diameter difference between Type L and M affect water flow?

Because Type L has thicker walls, its inner diameter is slightly smaller than Type M of the same nominal size. This means that, theoretically, Type M could allow for slightly better water flow and less pressure drop over a long run due to less friction. However, in practice, for residential systems with standard pipe runs, this difference is negligible and is far outweighed by the pressure rating and durability advantages of Type L.